Carbon Footprint – CO2

PCC BakkiSilicon hf. has been designed as one of the most climate-friendly and environmentally compatible silicon metal plants in the world. The use of Iceland´s geothermal resources in the silicon metal production cuts greenhouse gas emissions by around two-thirds as compared to other plants around the world. With silicon metal production at the PCC plant powered entirely by renewable energy, the CO2 footprint of the overall process is drastically reduced.

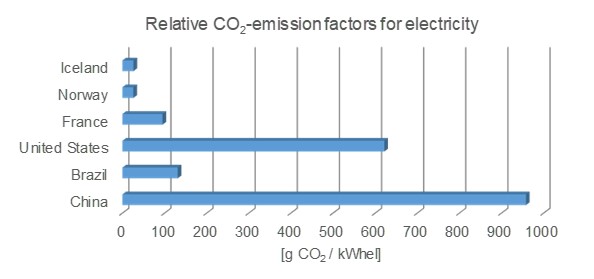

Iceland offers besides Norway (from Selection Countries) the best emission factor for electricity generation (incl. upstream processes) in terms of CO2 emissions:

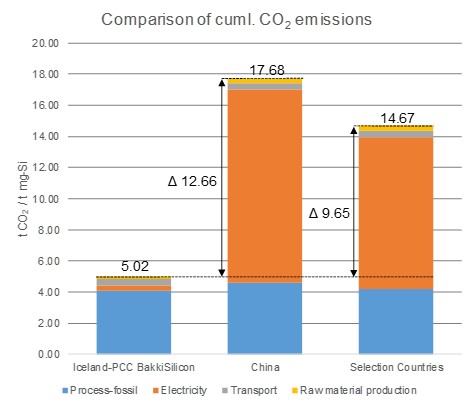

The cumulative CO2 emissions of a silicon metal plant in China – by far the world´s largest producer – are about 3.5 times higher on average than those of the PCC BakkiSilicon plant in Iceland. And CO2 emissions in the five most important producer countries – China, Brazil, the USA, France and Norway – are also almost three times higher than those of the PCC plant.

Based on the production capacity of 32,000 metric tons per year of silicon metal, the production process in the PCC BakkiSilicon plant

– avoids 405,120 t cumulative CO2 when compared to the average Chinese production conditions or

– avoids 308,800 t cumulative CO2 when compared to the Selection Countries (China, Brazil, USA, France and Norway).

EMU e. V. – Institute of Energy Systems, Material and Environmental Engineering e. V.

The Institute’s non-profit statutory objective is to support research at the Ruhr-Universität Bochum.